Hydrogen logistics Pt 2: future methods, costs, and a guess at the amount stored tomorrow

Last week I explored the current costs and methods used for hydrogen logistics today. This week will be about the future of this part of the value chain: what new methods are in the process of being developed and commercialized?

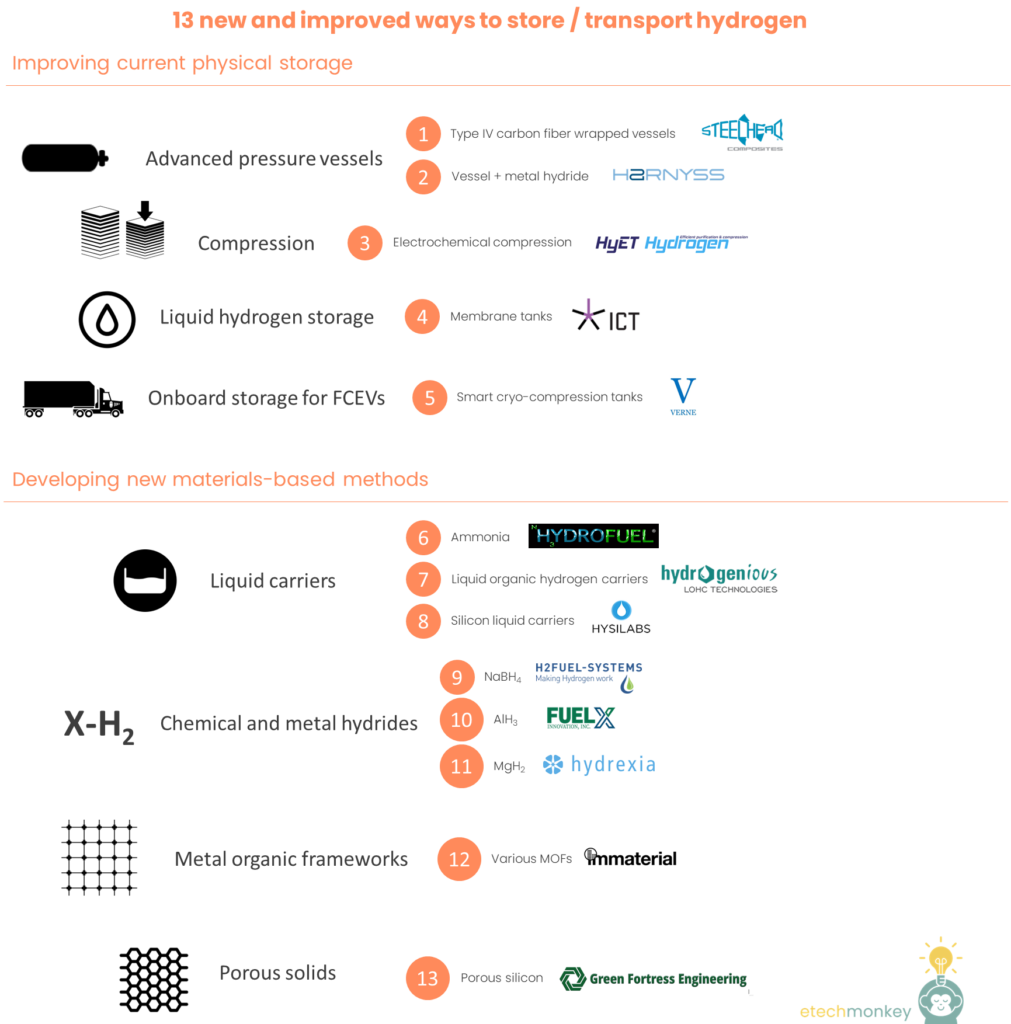

Innovation in storage seems to be bifurcated between 1) improvements to current physical methods and 2) developing new materials or molecules to capture and/or transform the hydrogen. Most startups and research labs seem to be working on #2, which is perhaps a symptom of the fact that there are an incredible number of materials to explore for this application. In fact, the DOE hosts a great database that lists out 250+ hydrogen-storing materials that researchers have discovered.

I won’t come even close to going into all of those methods, but hopefully the below gives a high level overview of what methods are actually being worked on by startups in the ecosystem.

(Note that these are not vetted or sorted. This is just a list I compiled of advertised hydrogen storage methods from various startups):

- Improving current physical methods

- Pressure vessels for gaseous storage of hydrogen still have room to advance. For example, Steelhead Composites creates type IV vessels, which are lined carbon-fiber wrapped vessels that are lighter, more durable, and can withstand greater pressures than traditional steel containers. Other vessels can be combined with a metal hydride to lower the needs of compression while increasing capacity (Harnyss)

- Not exactly a storage method, but upgraded compression technology like electrochemical compression developed by HyET can help increase availability and reduce the implementation cost of high-pressure storage

- Liquid hydrogen storage is also improving. IC Technologies in Norway has been working on new membrane tanks for large volume cryogenic liquid storage of hydrogen

- Improving onboard storage systems for hydrogen FCEVs is also another target of innovation. Verne’s system claims to offer cheaper, denser, safer, and more reliable tanks for trucking and shipping through cryo-compression and upgraded control systems

- Developing new materials-based methods

- New liquid carriers that allow transportation of hydrogen as a liquid fuel but without the expense of liquefication and/or cryogenic cooling. Liquid carriers most commonly mean ammonia (Hydrofuel / Kontak) and liquid organic hydrogen carriers (Hydrogenious), though there are novel inorganic liquid carriers like the silicon-based liquid carrier that HySiLabs is working on

- Metal and chemical hydrides like with sodium borohydride (H2Fuel Systems), aluminum hydride (FuelX), and magnesium hydride (H2Store / Hydrexia) have been pointed to as some of the most promising materials-based storage methods due to the high availability and low expense of the metals used. The limiting factor has been the energy needed and slow kinetics of the dehydrogenation reactions (“unpacking”), which has prevented rapid scale up

- Metal organic frameworks (MOFs) like those produced by Immaterial Labs can be used to adsorb hydrogen into the lattice at very high rates. MOFs do very well in terms of capacity and adsorption rates compared to competing methods but unfortunately usually have to operate in cryogenic temperatures, which drives up costs

- Similar to MOFs, porous solids can be used to absorb hydrogen. It was difficult to find any companies working on carbon nanotubes or activated carbon, which have long been discussed in research. In a related vein, a company called Green Fortress Engineering is developing hydrogen storage via porous silicon

Distributed hydrogen production does somewhat belong in this section too. Having onsite production at demand points like fueling stations eliminates the need for any hydrogen transport. Companies like IVYS Energy are working on building these all-in-one fueling stations.

It’s also worth mentioning the prospect of shipping hydrogen. Maritime transport of hydrogen is still in its infancy. It will be interesting to see whether or not international shipping of hydrogen will be necessary given the widespread availability of hydrogen-bearing sources. There are also some efforts in recent years to test out actually producing (then shipping) hydrogen on ships.

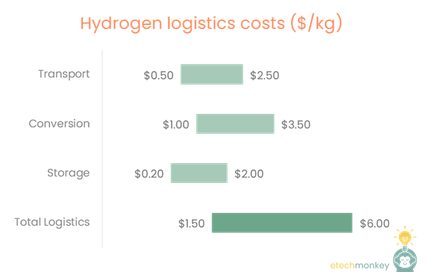

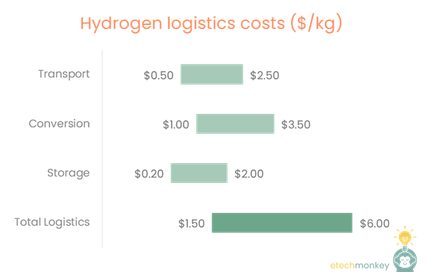

In terms of costs, there aren’t great sources for the potential costs of transport in the future based on all of the methods described above. According to one study examining Germany by 2050, transport + logistics could get down to $0.30 - $1.60 / kg vs. the ~$1.50 - $6.00 / kg range we determined last time for current methods. This study only looked at gas, liquid, and LOHC methods though.

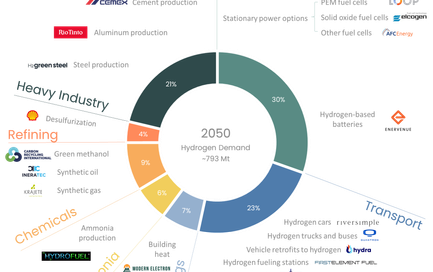

Finally, I’ll just end on the size of the future market. Luckily, this was actually a bit easier to find than the size of the current market, thanks to the smart people at IEA. According to their Net Zero scenario, they believe storage needs could amount to ~50 Mt by 2050, which is just under 10% of the 500+ Mt of hydrogen that they believe will be needed for Net Zero. That is a lot of hydrogen to store, considering the current total hydrogen produced right now is ~70 Mt. But considering the number of new methods that are under development, I'm optimistic that we'll have plenty of economic storage by that point.